Ultraviolet Laser Marking Machine

Ultraviolet laser marking machine belongs to a series of laser processing technology. It uses 355nm UV laser as the light source. The machine uses third-order intracavity frequency doubling technology to compare with infrared laser (pulsed fiber laser), 355 ultraviolet focusing spot. Small, can greatly reduce the mechanical deformation of the material and has little influence on the processing heat, because it is mainly used for superfine marking, engraving, cutting and the like. It is especially suitable for applications such as marking of food and pharmaceutical packaging materials, micropores, high-speed division of glass materials, and complex graphic cutting of wafers.

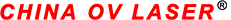

UV laser marking machine is mainly composed of ultraviolet laser (355nm violet light), laser power supply system, acousto-optic Q-switched system (including sound and light Q-switched crystal and driver), high-speed scanning galvanometer and beam expander focusing system, red light system, industrial Control cabinet or cabinet, laser power supply, dedicated control software and computer.

Main features of UV laser marking machine:

Laser (light source): 355 nm UV laser

Air-cooled device, small size, 20,000 hours maintenance-free (theoretical 20,000 hours of service life)

More than 5W power requires water cooling, distilled water or pure water.

The focused spot is extremely small, and the processing heat affected zone is small (cold light), making the material heat-receiving area smaller. Not susceptible to heat deformation, ultra-fine marking, special material marking

Low cost of use, better beam quality, high efficiency, low power consumption, more energy saving and environmental protection.

Can be applied to high-end market, ultra-fine marking environment, cosmetics, pharmaceuticals, LCD liquid crystal, electronic components, communication equipment, food and medicine packaging, glass division, electronic components, metal jewelry marking.

Ultraviolet laser technology is processed into cold processing because the high-energy molecules of ultraviolet photons directly separate the molecules on the metal or non-metal materials that need to be processed. However, this separation causes the molecules to be separated from the materials. This way of working will not Producing heat, because this does not produce heat, the way of UV laser processing becomes cold processing, which is also the difference from traditional laser technology.

On the basis of cold processing, the effect of processing product materials will get better results and better development. When using cold laser processing, the probability of material influence is reduced to one percent, so that the advantages of processing are obtained. All applications are also a major improvement in laser technology, and UV lasers will become more and more popular.

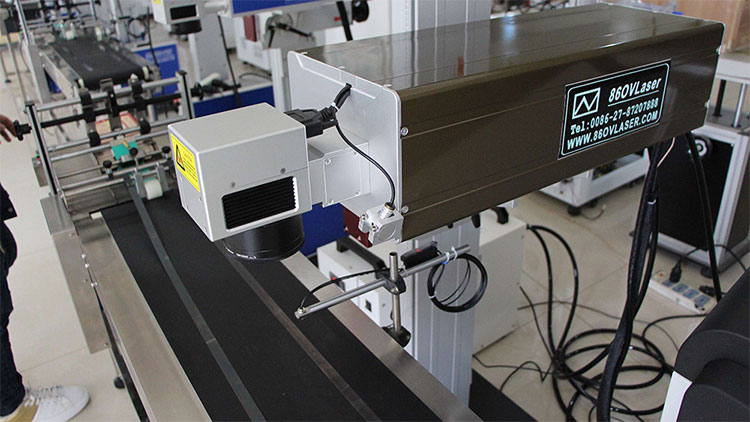

According to the model, it is mainly divided into: cabinet type, split type, flying type (online or assembly line), desktop type, large enclosed type, small enclosed type, electric door type and various non-standard forms

The function division according to the model is mainly as follows: the marking surface is a flat type (the workpiece plane, the curved surface with a small curvature); the end surface

Rotary type: The workpiece is a cylinder type, and the round enamel is marked in the circumferential direction (360 degree direction) (either the circumferential surface or the flat surface).

3D working type: 3D solid surface marking function, focusing spot is fine in the range of 1~60mm (drop) height, can realize laser marking on curved surface (spherical) workpiece more accurately, no defocusing during processing, through 3D dynamic laser Mark control hardware, software, configuration dedicated three-dimensional galvanometer, perfect control laser beam marking on any three-dimensional surface. The market is small and non-primary.

Working principle

The laser is output by the ultraviolet laser, and is focused by a high-speed XY galvanometer scanner onto the working surface by an F-θ lens to form a high-power density spot to photochemically react on the surface, so that the ultraviolet laser can obtain excellent beam quality under high power operation. And a narrower laser pulse width. The laser energy is amplified and shaped to form a usable laser beam, which is melted at a high speed to form a certain depth of dent, thereby marking a clear and beautiful mark on the workpiece, which is all done under computer control.

Main advantages

1. The latest marking software ZGGLASER 8.0 uses WINDOWS interface, powerful and compatible. It can directly retrieve DWG and DXF format graphics from AutoCAD2000. There are backup interfaces in the extended function, which can be used with some assembly lines. The software has data. The communication saves the network printing function, not only can save the marking content in the database, but also can call the data in other databases to be marked

2. Marking the workpiece does not require clamping and positioning, and loading and unloading is very convenient

3. There is no requirement for the hardness of metal parts, high and low can be marked, no pollution to materials and no deformation

4. There is no noise when marking work, the print content can be saved and saved, and serial number printing can be automatically performed;

5. The technology is very mature, reliable performance, high repeatability, high positioning accuracy, long continuous working time, fast marking speed, and very beautiful marking, and high resolution. The machine is small in size, long in life, reliable in performance, simple in installation and low in operating cost;

6. Compared with other laser marking machines, the violet laser is very efficient, the beam quality is better, the marking effect is finer and more perfect, and the parts are not replaced frequently. The laser power is more than 5W, and distilled water or pure water is needed. Can be up to 20,000 hours or more;

Applications: Very wide, all-encompassing, can be automated online

Ultraviolet laser marking machine is mainly based on its unique low-power laser beam. It is especially suitable for the high-end market of ultra-fine processing. The surface of packaging bottles for cosmetics, medicines, foods and other polymer materials is marked with fine results and clear and firm markings. Better than ink coding and no pollution; flexible pcb board marking, dicing; silicon wafer micro-hole, blind hole processing; LCD liquid crystal glass two-dimensional code marking, glassware surface drilling, metal surface plating marking, Plastic buttons, electronic components, gifts, communication equipment, building materials, etc.

Applicable to all metal materials and most non-metallic materials: coding, punching, laser tearing, stripping, stripping, rust removal, deep carving, fine micromachining, anodizing, oxygen-permeable conductive surface treatment Other applications

Main applications: film etching, glass marking, material micromachining, wafer cutting, laser rapid prototyping, etc.

1. Machinery industry: hardware tools, clutches, bearings, pistons, piston rings, steel pipes, steel plates, gears, sensors, shafts, etc.;

2. instrumentation: control panel, measuring tools, medical equipment, aviation parts, etc.;

3. Household appliances, lamps, product packaging, stationery, brand-name panels, label signs, cosmetics, color paper, various paint products, cigarettes, handicrafts, etc.;

4. Tableware, food, gold, jewelry, crafts, ceramics, building materials, sanitary ware, office supplies, etc.;